Introduction

Wuhan Boiler Company Limited Metal Materials Examination and Test Center was established in 1998. In October 1998 the quality system was set up basing on the elements of ISO/IEC Guideline 25-1996: General Requirements for the competence of Testing and Calibration of Laboratories. In 2000, the center passed the certification of CCIBLAC, in 2003, the center passed the certification of CNAL, the center got the qualification of CNAS and then the certification was kept up to now. It has been qualified by China National Accreditation Service (CNAS) for Conformity Assessment as national accredited Laboratory, and can meet the requirements of ISO/IEC17025. It is known that the center is the first lab to get this qualification in domestic boiler industry. The current lab building was put into use in 2009. In the early stage of construction, the group company planned to build the testing center into a global material research and development center. The testing center is built with advanced standards both in our country and abroad, so that the testing center has advanced and complete facilities for temperature and humidity control, ventilation, and safety, and the layout is scientific and reasonable. Now The testing center has now developed into a comprehensive laboratory integrating physical and chemical performance testing of metal materials, non-destructive testing, new material research, material failure analysis, and on-site testing services and so on.

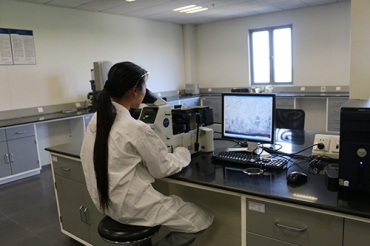

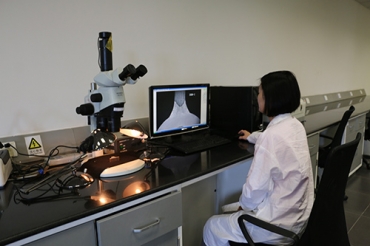

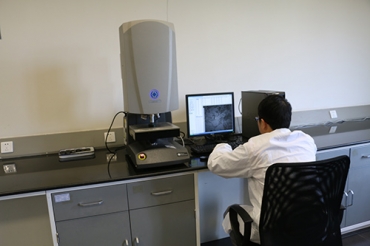

The Center possesses world leading test instruments and professional testing engineers in the areas of chemical analysis, metallographic analysis, hardness test, mechanical property test, failure analysis, NDT and so on. Now the center is open to external to carry on professional work including the material failure analysis and remaining life assessment, new material research and performance study, NDT, manufacturing procedure qualification like welding and bending of metal materials, test and inspection of raw metal materials and products including welding materials, on-site service including NDT and metallographic analysis, technical advisory services and so on.

Qualification

Business Scope

|

Chemical analysis |

Metallography analysis |

|

Ferro-alloys |

Macro structure analysis |

|

Carbon steel/Alloy steel |

Micro structure analysis |

|

Stainless steel |

Non-metallic inclusion analysis |

|

Nickel base alloy |

Decarburized layer |

|

Super-alloy |

Grain size |

|

Welding material |

Intergranular corrosion |

|

Others |

Fracture analysis |

|

Mechanical property test |

NDT |

|

Bending test |

Visual inspection |

|

Flaring test |

Endoscopy |

|

Flattening test |

Dimensional Measurement |

|

Tensile test(Including high temperature test) |

Ultrasonic automatic inspection system |

|

Impact test (high &low temperature) |

Routine Ultrasonic inspection—PE Technic |

|

Others |

Eddy current automatic inspection system |

|

Failure analysis |

Hardness test |

|

Metal product and component |

Brinell hardness test |

|

Field metallographic analysis |

Rockwell hardness test |

|

Field ultrasonic test |

Vickers hardness test |

|

Root cause analysis of material failure |

Micro Vickers hardness |

|

Remaining life assessment |

Field hardness test |

Advanced Equipment